| Ch 3. Beam Shear/Moment Diagrams | Multimedia Engineering Mechanics | ||||||

|

Shear and Moment |

Shear/Moment Diagrams |

Moving Loads |

|||||

| Shear/Moment Diagrams | Case Intro | Theory | Case Solution | Example |

| Chapter |

| 1. Stress/Strain |

| 2. Torsion |

| 3. Beam Shr/Moment |

| 4. Beam Stresses |

| 5. Beam Deflections |

| 6. Beam-Advanced |

| 7. Stress Analysis |

| 8. Strain Analysis |

| 9. Columns |

| Appendix |

| Basic Math |

| Units |

| Basic Mechanics Eqs |

| Sections |

| Material Properties |

| Structural Shapes |

| Beam Equations |

| eBooks |

| Dynamics |

| Fluids |

| Math |

| Mechanics |

| Statics |

| Thermodynamics |

| ©Kurt Gramoll |

|

|

||

| Introduction |

||

|

|

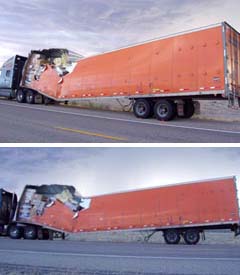

"Well, this is a new one for me" said the highway patrolman when he was called to investigate the accident. "I have never seen a semi snap in two due to the load. I wonder why it failed near the front and not in the middle?" His partner added, "I am sure the investigation team will let us know. I wonder if the truck was overloaded?" What is known:

|

|

| Question |

||

Assumed Location of Trailer Supports |

Does the failure location agree with a basic beam analysis? What is the value of the maximum bending moment and does it exceed the design moment of 200 kip-ft? |

|

| Approach |

||

|

||

Practice Homework and Test problems now available in the 'Eng Mechanics' mobile app

Includes over 500 free problems with complete detailed solutions.

Available at the Google Play Store and Apple App Store.